Everything You Need To Know about Kota Doriya Sarees

The elegant hand crafted fabric from Kota, Rajasthan

Speaking about the traditional handicrafts of India, one can just not miss to mention the Kota Doriya saress.

Kota Doriya gets its name from Kota, a place in Rajasthan, where the sarees are generally manufactured; while “Doriya” means thread.

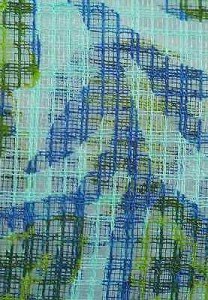

The distinct looking fabric, with its brilliant square pattern, is every craft lover’s delight. The supremely airy and lightweight fabric is very comfortable to be worn in summers and demands less maintenance, making it one of the favorites of the traditional population.

The Origin

The discrete weave was originated in Mysore. It was in the late 17th century, that Maharao Kishore Singh, a general of the Mughal army, brought the weavers from Mysore to Rajasthan. These weavers were called as Masurias and the Kota doriya sarees have since then been also called as Kota Masuria sarees.

The sarees are manufactured mainly by the Ansari community of the erstwhile Kota state and the ‘Hadauti’ region. Today, the villages in outskirts of the Kota city is where mostly all the weavers are concentrated.

The major location of the weavers is the Kaithun (or Kaithoon) village, which is about 15 km from Kota. there are nearly 1500 weavers in this cluster. Apart from Kaithun, a few craftsmen pursue this craft in the adjacent districts of Bundi and Baran. Kota sari is another name which is commonly used for the Kota Doriya sarees.

Major attributes of the Kota Doriya

The unique weave:

The Kota Doriya has a very distinct look- the square  patterns. These squares are referred to as ‘khats’. The checkered weave of the Kota sari , made on the traditional pit looms, is one of its kind.

patterns. These squares are referred to as ‘khats’. The checkered weave of the Kota sari , made on the traditional pit looms, is one of its kind.

The Kota Doriya is the finest open weave fabric of India. The conventional fabric is made by 300 to 350 Khats made across the width of the fabric. Each khat is made by eight cotton and six silk yarns.

The colors:

The Kota Doriya sarees were in white or beige colors  originally. However, with the advent of modern technologies, tastes and the passing time, Kota sari of almost every possible color is now available.

originally. However, with the advent of modern technologies, tastes and the passing time, Kota sari of almost every possible color is now available.

The Fabric:

The fabric of these sarees is either pure silk, cotton or a blend of the two. Silk was introduced in the initially pure cotton sarees in order to provide shine and transparency to the fabric while cotton gives the necessary strength.

The strengthening technique:

An interesting feature of the  Kota Doriya is the application of onion juice and rice paste on the yarn which strengthens the yarn. The technique is so efficient that there is no need of any additional finishing.

Kota Doriya is the application of onion juice and rice paste on the yarn which strengthens the yarn. The technique is so efficient that there is no need of any additional finishing.

Varieties:

Making them versatile, three different styles of Kota Doriya sarees and suits are available- basic (plain), printed and zari. The basic one is has checks made of slightly rough cotton (or plain gold threads), the printed ones usually have block printing on them which look graceful and fresh, yet traditional while the zari work gives a slight heaviness and style to the regular sari/ suit. Embellishments of all sorts are used to make them further decorative.

Easy maintenance:

The Kota Doriya sarees are mostly in cotton and hence not very difficult to maintain. Cold water washing with shadow drying are the major maintenance requirements of the fabric making it quite preferred by women.

The fabric characteristics:

The Kota Doriya fabric is a lightweight, soft, thin, airy, translucent and gossamer fabric which not only has a distinct look and feel but is also very comfortable to wear.

The Process

Kota Doriya is produced on the very traditional and age-old pit looms with throw shuttle technique. All the processes are carried out manually.

Winding:

The yarns obtained by the weavers is in the form of ‘lachhis’ or hanks which require winding before being used on the loom for weaving. Winding is the process of transferring yarn from these hanks on to bobbin for warp and on pirn for weft. The pirn winding is done using a small swift/ ‘charkha’ consisting of rotary wheel attached to harness on conveyor belt giving a similar rotary motion to the spool mounted at the other end. Rotation of the wheel by hands results in the rotation of the spool and thereby the thread is wound on small spindles.

Warping:

Warping is the process of obtaining a predetermined length of warp having desired number of threads that shall be needed for the complete width of the fabric. The warping method prominently used for Kota Doriya is ‘peg warping’. Pegs are placed along the full length of the yarn so as to get a continuously crisscrossed set of two yarns for weaving. The criss crossing is helpful to find out the broken yarn on the loom during weaving.

Dyeing:

The yarns are dyed (or colored) manually by dipping them in utensils filled with heated water and pre-dissolved dyes.

Sizing:

Sizing is done in order to impart strength to the yarn and is required mainly in cotton. A thin rice paste (‘maandi’) and juice of locally available wild onion is used for this purpose. The onion juice makes the yarn soft and lustrous and it remains so even after multiple washes.

Drafting-Denting-Piecing:

All individual cotton and silk threads are drafted through double clasped country cotton heald (‘Ranch’) and dented through dents of bamboo/ steel reed (‘Fani’) in a particular pattern to produce the checks or ‘khat’ along with the weft. Since drafting and denting of individual threads is time-consuming, an alternative method called piecing is used in which the individual new threads of the warp are tied to the corresponding threads of the previous leftover warp.

Weaving:

Weaving is done on the pit looms by throw shuttle technique. It is done so skillfully that almost uniform size of the ‘khat’ or the check pattern is produced.

Designing:

The designs to be produced are first made on graph paper and then transferred to the fabric through various techniques.

Kota Doriya products

The various products include the Kota Doriya or Kota sari, suits, dupattas, dress materials and furnishings.

The current scenario

The Kota Doriya weaving is a very tedious task involving a number of process that require skill, precision, patience and concentration. It is essentially a craft whose skill is passed on from one generation to other. The craft is declining not only due to the poor conditions of weavers, but also due to the severe competition Kota Doriya faces from fake products as well as other crafts such as Maheshwari weaving. The protection and safeguard of the original Kota Doriya is hence the need of the hour. As far as the fake products are concerned, a promotion in the interest of making the customers well informed about the Kota Doriya fabric is required. The hallmarks and GI patents exist, but are little known to the customers.

Apart from the above stated threats to the Kota Doriya industry, the demand of Kota Doriya products need to be increased with creating an awareness about its unique qualities. The current demand in the country is majorly from the ‘Marwari’ and ‘baniya’ communities and a little demand from other countries and an improved marketing effort by the government is essential. The Kota Doriya craft has its own individuality and exclusivity and the market is certainly growing, though gradually. With the evolution of techniques and better designs, the demand is definitely set to grow in both domestic and international markets and appeal not just traditional but fashion conscious populat

ion as well.